-

E-mail

Austin120521@outlook.com -

E-mail

sales@jujiuhouse.com -

Telephone

+86-17864099991 -

Telephone

+86-17854044442

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

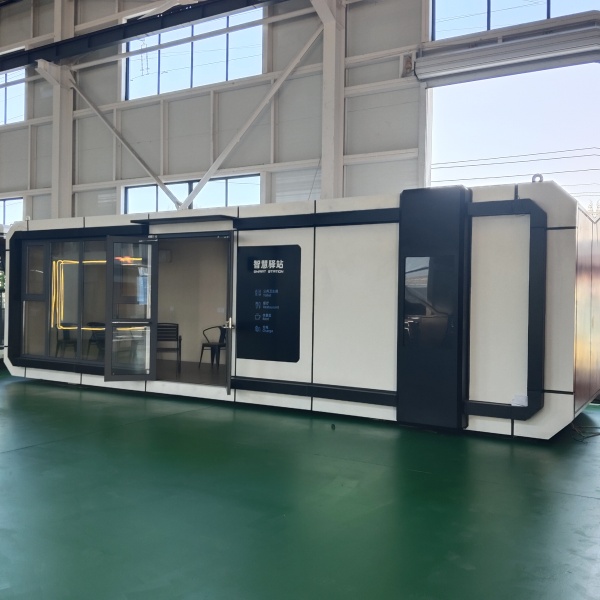

China low price flat pack container house prefabricated

Exploring the World of Low-Cost Flat Pack Container Houses in China

China has become a hub for low-cost, prefabricated housing, particularly the flat pack container house. These structures offer flexibility and affordability, making them an intriguing option for many around the globe. As someone who's been in the integrated housing industry for years, I've seen firsthand the benefits and occasional pitfalls of these systems.

The Rise of Prefabricated Container Houses

The concept of the flat pack container house is straightforward: factory-built modules that are transported to the site and assembled. This method cuts down on construction time and reduces costs, which is attractive for developers and end-users alike. But there’s more beneath the surface. The simplicity of the idea belies the complexity of its implementation, especially when scaling up for large projects.

Take, for example, my experiences with SHANDONG JUJIU INTEGRATED HOUSING CO,LTD. This company has been pioneering in this space, deploying prefabricated solutions efficiently across different regions. Their expertise ranges from light steel villas to curtain wall engineering. Each project demands a tailored approach to meet specific site conditions and client expectations.

One intriguing aspect is how Chinese manufacturers can offer such competitive prices. Cost efficiency stems from economies of scale, streamlined logistics, and advanced production techniques honed over years of industrial evolution. However, the initial attraction to low price tags can sometimes lead clients to overlook crucial details like insulation and local compliance standards.

Understanding the Manufacturing Process

Diving deeper into the manufacturing process, companies like Shandong Jujiu focus on integrating R&D with efficient production lines. The production involves several stages, from design conceptualization to structural optimization. It's fascinating how a basic skeleton can be transformed with steel panels, insulation materials, and various finishes to achieve both functionality and aesthetic appeal.

From a practical standpoint, one must always evaluate the trade-offs. Lower costs can sometimes mean basic configurations, which might not suit all climates or architectural preferences. Customization can address these, but it comes with added costs. This is where industry experience becomes invaluable—knowing which adjustments bring the best return on investment is key.

That said, there have been scenarios where projects encountered unforeseen hurdles. Transport logistics can get tricky, especially with international shipping. Moreover, understanding local building codes is non-negotiable to avoid legal entanglements.

Installation and On-Site Challenges

Having been part of various site installations, I can attest to the importance of a meticulously planned setup phase. The devil is in the details: accurate alignment, secure fixing, and seamless module integration. These might seem trivial but have significant long-term implications for structural integrity and user satisfaction.

One memorable project involved setting up a housing complex in an area prone to earthquakes. The design adjustments required for seismic activities revealed much about the system’s inherent resilience and flexibility. It's these adaptations that often highlight the true capabilities of a prefabricated system.

Despite potential challenges, the appeal of quick setup and reduced labor costs remains strong. It's crucial, though, for installers to have thorough training — something companies like Shandong Jujiu emphasize. Such preparation not only ensures a smoother process but also enhances the final quality of the build.

Customization and Consumer Needs

Every client comes with unique needs, and the prefabricated house market is no exception. Customization is where innovation meets practicality. The versatility of flat pack container houses allows for multiple uses—from residential homes to commercial pop-up spaces.

I've observed that the degree of customization requested often correlates with project scale. Larger projects tend to have stricter budget constraints but still require a touch of personalization. Smaller setups might allow for more creative freedom, following specific design philosophies or functional requirements.

Collaboration between design teams and clients is critical here. It’s about finding common ground, balancing uniqueness with feasibility. And companies like Shandong Jujiu, accessible at jujiuhouse.com, play a pivotal role by offering insight-driven design solutions that cater to these diverse demands.

Conclusion: Weighing the Pros and Cons

Ultimately, the attraction to China's low-cost flat pack container houses is understandable, given the economic benefits. But every savvy developer or homeowner must look beyond the sticker price. It’s essential to consider quality, adaptability, and compliance, ensuring that the choice of prefabricated housing aligns with long-term goals and environmental conditions.

Reflecting on decades of industry involvement, it’s evident that the potential of prefabricated housing is immense when executed correctly. Lessons learned from projects—successful or otherwise—highlight the necessity of experience, rigorous planning, and an understanding of the intricate dynamics at play.

For those new to the world of integrated housing or considering their first flat pack project, engaging with a competent partner like Shandong Jujiu Integrated Housing Co., Ltd. can provide the expertise required to navigate this evolving landscape effectively.

Related products

Related products

Best selling products

Best selling products-

Luxury High Quality 2 Bedroom Container Home Prefabricated Steel Space Capsule for Office Shop Hotel or Outdoor House

Luxury High Quality 2 Bedroom Container Home Prefabricated Steel Space Capsule for Office Shop Hotel or Outdoor House -

The foldable container house with side wing design can be quickly set up and is suitable for various environments.

The foldable container house with side wing design can be quickly set up and is suitable for various environments. -

Easy Install Customized Detachable Container Homes Extendable House Prefab 2 Floors Expandable Container House

Easy Install Customized Detachable Container Homes Extendable House Prefab 2 Floors Expandable Container House -

Modular modern movable apple cabins, customized high-end folk houses and portable bedrooms, delivered as a whole

Modular modern movable apple cabins, customized high-end folk houses and portable bedrooms, delivered as a whole -

Stair Access Double Wing Expandable Container House | Easy Installation Mobile Office

Stair Access Double Wing Expandable Container House | Easy Installation Mobile Office -

Dual-Wing Folding Container House: Fast Assembly, Space-Saving & Multi-Scene Adaptable

Dual-Wing Folding Container House: Fast Assembly, Space-Saving & Multi-Scene Adaptable -

Luxury Foldable Two Story Container House for Glamping Resort and Villa Hotel

Luxury Foldable Two Story Container House for Glamping Resort and Villa Hotel -

Factory Direct Sales Office Folding Container Luxury House Living Container House

Factory Direct Sales Office Folding Container Luxury House Living Container House -

A container house with a terrace and double-wing folding design, suitable for various purposes such as offices, meeting rooms, living rooms, etc.

A container house with a terrace and double-wing folding design, suitable for various purposes such as offices, meeting rooms, living rooms, etc. -

Two Wing Folding Expandable Container House

-

Waterproof folding container house – mobile accommodation for campsites/scenic spots

Waterproof folding container house – mobile accommodation for campsites/scenic spots -

Outdoor ecological capsule rooms, luxury pods, space capsule hotel rooms, prefabricated space capsules, container houses

Outdoor ecological capsule rooms, luxury pods, space capsule hotel rooms, prefabricated space capsules, container houses

Related search

Related search- Buy bedroom space capsule

- China portable homes that fold out

- prefabricated expandable container house

- Buy low price expandable container house 20ft

- fold out homes from shipping containers

- prefabricated folding container house

- Buy 40ft expandable container house

- Buy relocatable shipping container home expandable granny flat portable tiny house

- China space capsule villas

- China prefab cabin container house