-

E-mail

Austin120521@outlook.com -

E-mail

sales@jujiuhouse.com -

Telephone

+86-17864099991 -

Telephone

+86-17854044442

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

China modern space capsule

Understanding the Evolution of China's Modern Space Capsule

When we talk about a China modern space capsule, the conversation often drifts to grand expectations and speculations. Many outside the industry think it's all about cutting-edge technology and seamless execution. However, the reality on the ground—or in space—is far more nuanced. There's a hidden story of iteration, adaptation, and the unexpected discoveries that often overshadow well-laid plans.

Early Challenges and the Learning Curve

The journey of China's space program, including its work on the modern space capsule, is deeply rooted in overcoming early challenges. Initial designs faced multiple iterations. Failures, in practice, became just as informative as successes. Engineers grappled with everything from material weaknesses to unexpected stresses during re-entry. Unlike the polished surface often presented, initial tests were rife with surprises.

Back then, the learning curve was steep. Teams would often rely on manual calculations, pencil sketches, and wind tunnel tests. You gain a unique respect for the basic principles of physics when the simulations don't go as planned. It becomes apparent that every setback is a step closer to understanding the intricacies of capsule design.

There's also the underappreciated challenge of integrating new technologies with existing infrastructure. Most aren't aware that innovations like advanced heat shields and improved thruster systems often conflict with older components. This is where the “modern” part of the capsule shines—melding the old with the new.

Material Innovation and Testing

One of the most significant obstacles has always been material science. Contemporary crafters of the China modern space capsule have had to innovate new heat-resistant materials to withstand re-entry temperatures. The testing process for these materials is extensive and complex, demanding a marriage of new-age composites and traditional engineering wisdom.

In one instance, an entire batch of components was retooled after discovering unexpected deformation under intense temperature fluctuations. This was a defining moment, cementing the approach that enduring solutions often emerge from the crucible of failure.

The result of these trials is a robust, lightweight material that can endure repeated cycles, showcasing how far material science has come in contributing to the space program's ambitions.

System Integration and Cross-Disciplinary Collaboration

The development of a China modern space capsule is not just an engineering task; it's a symphony of cross-disciplinary collaboration. Software engineers, mechanical engineers, and material scientists work in unison. Each brings a slice of the puzzle, gradually piecing together the complex picture of a functional capsule.

An often overlooked aspect is how these teams operate. It's an intricate dance of back-and-forths, sometimes pivoting on daily meetings that last into the late hours. Here, expertise from companies like SHANDONG JUJIU INTEGRATED HOUSING CO, LTD (https://www.jujiuhouse.com) comes in handy. Known for their proficiency in integrated design and production—albeit in housing—their practices often mirror what's needed in aerospace: meticulous planning and seamless execution.

Bridging the gap between various systems—navigation, communication, and life-support—is a defining challenge. Systems must resist both the harshness of space and the minutiae of human error. It's about maintaining equilibrium in an environment that's anything but forgiving.

Practical Deployment and Real-World Outcomes

When prototypes transition to real-world deployment, the excitement is palpable. Yet, veteran engineers know that the operational reality can deviate significantly from controlled tests. Unforeseen solar flares or micrometeoroids are constant reminders that the cosmos is unpredictable.

This is where contingency planning becomes paramount. Engineers embed redundancies and create robust backup systems to tackle potential hiccups. Interestingly, the majority of real-world problem-solving hinges on quick thinking and the ability to adapt, skills honed through rigorous preparation and experience.

It's during these missions that the true capability of the space capsule is tested. And it's an ongoing process; every mission continues to feed valuable data back into the system, refining future designs.

The Future Horizon

Looking ahead, the realm of China modern space capsules continues to evolve. It's a quest driven by both national pride and scientific curiosity. Each launch improves on its predecessors, informed by a rich history of successes and setbacks.

The next frontier involves longer missions, exploring farther into space. As these capsules transform to accommodate extended stays, they will increasingly rely on lessons from other industries, like those of Shandong Jujiu Integrated Housing Co., Ltd., to optimize living spaces aboard spacecraft.

Ultimately, the story of a modern space capsule is one of relentless innovation fueled by an insatiable drive to venture into the unknown. It's a testament to human ingenuity—adapting and redefining what's possible in the exploration of space.

Related products

Related products

Best selling products

Best selling products-

Customized Two Wing Folding Expandable Container House

Customized Two Wing Folding Expandable Container House -

Good Quality Modular Homes Prefabricated House Expandable Container House 20FT Mobile Flat Roof House

Good Quality Modular Homes Prefabricated House Expandable Container House 20FT Mobile Flat Roof House -

Reasonable Price 1 Bedroom Modular Container House Folding Container Home for Villa or Apartment Use

Reasonable Price 1 Bedroom Modular Container House Folding Container Home for Villa or Apartment Use -

Factory Direct Sales Office Folding Container Luxury House Living Container House

Factory Direct Sales Office Folding Container Luxury House Living Container House -

Modular modern movable apple cabins, customized high-end folk houses and portable bedrooms, delivered as a whole

Modular modern movable apple cabins, customized high-end folk houses and portable bedrooms, delivered as a whole -

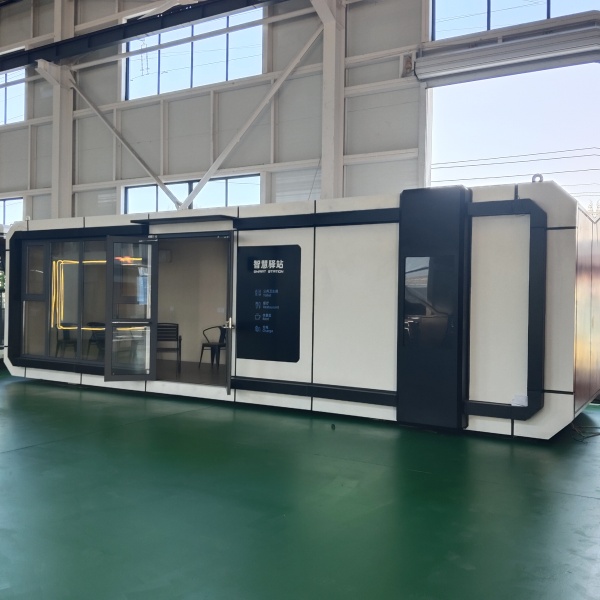

Standard Modern Camping Pod Space Prefabricated Portable Mobile Capsule Room Hotel Bathroom Prefabricated Spaceship House

Standard Modern Camping Pod Space Prefabricated Portable Mobile Capsule Room Hotel Bathroom Prefabricated Spaceship House -

Luxury High Quality 2 Bedroom Container Home Prefabricated Steel Space Capsule for Office Shop Hotel or Outdoor House

Luxury High Quality 2 Bedroom Container Home Prefabricated Steel Space Capsule for Office Shop Hotel or Outdoor House -

Luxury Foldable Two Story Container House for Glamping Resort and Villa Hotel

Luxury Foldable Two Story Container House for Glamping Resort and Villa Hotel -

Outdoor ecological capsule rooms, luxury pods, space capsule hotel rooms, prefabricated space capsules, container houses

Outdoor ecological capsule rooms, luxury pods, space capsule hotel rooms, prefabricated space capsules, container houses -

Customizable Office Mobile Home with Flat Roof and Double Wing Expansion Box, Convenient Container

Customizable Office Mobile Home with Flat Roof and Double Wing Expansion Box, Convenient Container -

Luxury Prefabricated Living Container House Modular Glass Tiny House Prefab Container Home Apple Cabin

Luxury Prefabricated Living Container House Modular Glass Tiny House Prefab Container Home Apple Cabin -

Portable outdoor camping bathroom, mobile toilet, prefabricated modular villa & rental of outdoor and indoor showers

Portable outdoor camping bathroom, mobile toilet, prefabricated modular villa & rental of outdoor and indoor showers

Related search

Related search- China fold out homes

- modern durable quality expandable container house

- prefabricated expandable container house

- Buy container house

- Buy folding house price

- Buy the apple cabin

- prefabricated house folding container

- Buy foldable mobile container house

- China alibaba expandable container house

- luxury expandable container house