-

E-mail

Austin120521@outlook.com -

E-mail

sales@jujiuhouse.com -

Telephone

+86-17864099991 -

Telephone

+86-17854044442

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

wholesale 40 foot container house prefabricated

The Realities of Wholesale Prefabricated 40 Foot Container Houses

In recent times, the phrase wholesale 40 foot container house prefabricated has caught significant attention in the housing sector. It's tempting to see it as an easy, cost-efficient housing solution. However, things are never quite that straightforward. Let's delve into this burgeoning industry, punctuated by stumbling blocks, revelations, and real-world insights.

Understanding the Prefabricated Market

Walking the halls of possibilities in the prefabricated housing market, you quickly realize that not all 'affordable' solutions are created equal. The appeal of the 40 foot container house primarily lies in its upfront cost and quick setup. But dig a little deeper, and a myriad of other factors starts shaping the true cost.

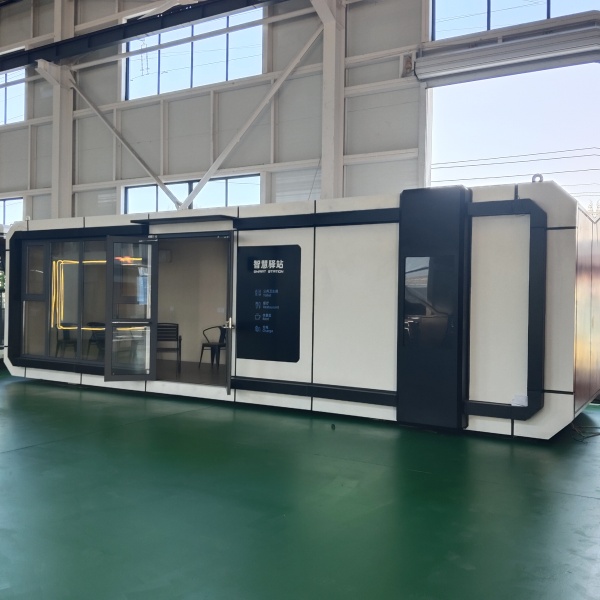

Take Shandong Jujiu Integrated Housing Co., Ltd., a notable name in this field. With a website at jujiuhouse.com, they exemplify a successful model in the integrated housing industry. They specialize in a range of options from light steel villas to complex steel structure engineering, merging design and practicality. Yet, the logistics involved in transporting and setting up these giants often cost over half of the product price itself.

Versatility is another selling point. A well-thought-out container can transform into multiple living spaces or function as a temporary office. But then again, there's the local jurisdiction to consider—all too often, a deal-breaker.

Design and Customization Challenges

Design flexibility meets its limits when accommodating client-specific needs. Customization requests range from modified entry points to specialized insulation panels. Each adjustment invites a cost spiral that contradicts the initial 'saving promise.'

Shandong Jujiu adeptly navigates this through thorough initial consultations, avoiding pitfalls later. Their R&D and design services ensure plans are realistically grounded before resources are committed. Yet, skeptics often overlook the unseen costs of these adjustments.

Indeed, adapting infrastructure to existing landscapes or incorporating energy-efficient solutions adds layers of complexity. Here, prefab evolves from an appealing buzzword into a tangible engineering puzzle.

Installation Realities

Installation seems deceptively simple. The notion: receive your prefabricated units and voila! You're set. But reality disappoints. Whether it's zoning laws, site preparation, or simple manpower availability, unforeseen variables multiply.

Even with expert guidance from companies like Shandong Jujiu, logistical details can delay projects. Their integrated housing solutions often require tailored approaches, with an eye on aligning logistics seamlessly with structural realities.

The unseen challenge: fitting a 'one-size-fits-all' solution into the bespoke demands of new locales. No small feat.

Maintenance and Longevity

Durability of these structures often teeters on thin lines. Materials used in prefabricated housing dictate longevity but also involve trade-offs in aesthetic and sustainability considerations.

Corrosion, temperature control, and human wear and tear challenge these structures' integrity over time. Shandong Jujiu offers ongoing support post-installation, but the client's maintenance commitment largely decides the structure's lifespan.

Clients often underestimate these demands. The shine of a fresh build distracts from ongoing responsibilities—a notable pitfall for the unprepared.

The Way Forward

Given these variables, where do container houses fit in the broader housing landscape? Perhaps, as supplementary solutions. They excel in rapid-build scenarios like emergency housing or niche commercial applications.

Companies like Shandong Jujiu blend integrated housing insights with rigorous real-world application—guiding clients responsibly through the process. While success stories abound, they often hinge on meticulous planning and augmented expectations.

For those willing to navigate the intricate web of modular architecture, prefabricated 40 foot container houses offer exciting prospects—but only with eyes wide open and the willingness to adapt throughout the journey.

Related products

Related products

Best selling products

Best selling products-

Outdoor ecological capsule rooms, luxury pods, space capsule hotel rooms, prefabricated space capsules, container houses

Outdoor ecological capsule rooms, luxury pods, space capsule hotel rooms, prefabricated space capsules, container houses -

Two Wing Folding Expandable Container House

-

Easy Install Customized Detachable Container Homes Extendable House Prefab 2 Floors Expandable Container House

Easy Install Customized Detachable Container Homes Extendable House Prefab 2 Floors Expandable Container House -

Modular modern movable apple cabins, customized high-end folk houses and portable bedrooms, delivered as a whole

Modular modern movable apple cabins, customized high-end folk houses and portable bedrooms, delivered as a whole -

A container house with a terrace and double-wing folding design, suitable for various purposes such as offices, meeting rooms, living rooms, etc.

A container house with a terrace and double-wing folding design, suitable for various purposes such as offices, meeting rooms, living rooms, etc. -

Luxury foldable two-story container houses in luxury resort hotels and villa hotels

Luxury foldable two-story container houses in luxury resort hotels and villa hotels -

Factory Direct Sales Office Folding Container Luxury House Living Container House

Factory Direct Sales Office Folding Container Luxury House Living Container House -

Customized Two Wing Folding Expandable Container House

Customized Two Wing Folding Expandable Container House -

Luxury Foldable Two Story Container House for Glamping Resort and Villa Hotel

Luxury Foldable Two Story Container House for Glamping Resort and Villa Hotel -

The foldable container house with side wing design can be quickly set up and is suitable for various environments.

The foldable container house with side wing design can be quickly set up and is suitable for various environments. -

A container house with a terrace and double-wing folding design, suitable for various purposes such as offices, meeting rooms, living rooms, etc.

A container house with a terrace and double-wing folding design, suitable for various purposes such as offices, meeting rooms, living rooms, etc. -

Portable outdoor camping bathroom, mobile toilet, prefabricated modular villa & rental of outdoor and indoor showers

Portable outdoor camping bathroom, mobile toilet, prefabricated modular villa & rental of outdoor and indoor showers

Related search

Related search- economical prefabricated modular mobile portable container house

- China 15ftx 20ft mobile expandable prefab house mobile home prefab

- China luxury expandable container house

- Buy apple valley lake cabins

- China folding house container

- 40ft expandable container house usa

- Buy modular modern container house tiny home prefabricated

- china wholesale container prefabricate house

- China expandable prefab house

- modular modern container house tiny home prefabricated